Hidden title

In-page Navigation

What are Ajinomoto Fine-Techno's magnetic materials?

Ajinomoto Fine-Techno offers a full range of services from molecular design and formulation design to process development and solution proposals to meet customer requirements.

We provide soft magnetic materials that match the material properties and customer processes to meet the needs for higher performance in electronic devices, which are becoming increasingly precise and compact.

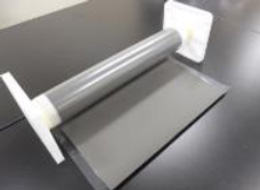

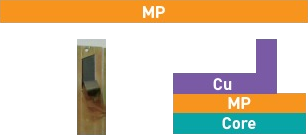

| AMF (AFTINNOVA® Magnetic Film) |

AMP (AFTINNOVA® Magnetic Paste) |

AMI (AFTINNOVA® Magnetic Ink) |

|

|---|---|---|---|

|

|

||

| Shape | Film | Liquid (without solvent) | Liquid (with solvent) |

| Procedure for use | Vacuum lamination, Vacuum heat press | Screen printing, Vacuum screen printing | Screen printing |

| Status | Mass production | Mass production | Under development |

We can provide magnetic materials in the form suiting the particular application.

Application

Servers, client terminals, data centers, mobile and in-vehicle devices, and more

Inductor

Improve inductance

Electromagnetic shield

Protects devices from electromagnetic waves

Wireless power transfer

Improve power supply efficiency

Transformer

Improve conversion efficiency

Low magnetic loss

Low loss is achieved even in high frequency bands.

Feature

#1

Embedding ability

Good embedding and surface flatnessLiquid type is compatible with vacuum printing.

Film type is available for either vacuum laminate or vacuum heat press.

Film type is available for either vacuum laminate or vacuum heat press.

Feature

#2

Plating compatibility

Good plate adhesion is achieved.

Feature

#3

The following is an explanation of the process once the application has been submitted.

Telephone or form inquiry

Inquire about customer issues, required characteristics

Propose and send samples for evaluation

Customer evaluation

Interview regarding results of evaluation