Ajinomoto Build-up Film® (ABF)

In-page Navigation

What is Ajinomoto's Insulation film (Ajinomoto Build-up Film® ABF) ?

Ajinomoto Build-Up Film® (ABF) is used as an insulating material for high-performance semiconductors (CPUs), which are the heart of personal computers. ABF currently boasts a share of nearly 100% of the market for Insulation film used in major personal computers worldwide.

Have you experienced these issues?

Irregular printing and bubbles occurring during liquid resin coating result in decreased yield

case

01

Need free control of conductor thickness

case

02

Eliminating steps such as copper foil removal from semi-additive process

case

03

Here is the product that resolves these issues.

Ajinomoto Build-up Film® (ABF)

Benefits of introduction

Compared with liquid coating materials Yield loss due to bubbles and irregular printing during liquid resin coating can be eliminated. Solvent is not volatilized, nor is the working environment degraded. Both sides can be processed simultaneously, resulting in high productivity and preventing problems caused by the warping of thin sheets. Surface smoothness is superior, and film thickness is easy to control.

merit

Part1

Compared with resin-coated copper foil (RCC)Advantageous for fine pattern formation

Easy etching in the panel plating method thanks to free conductor thickness control

Applicable to semi-additive process without extra steps such as copper foil removal

Easy laser processing

The process of copper foil removal prior to laser processing - which is necessary in the case of RCC - is no longer needed.

Easy etching in the panel plating method thanks to free conductor thickness control

Applicable to semi-additive process without extra steps such as copper foil removal

Easy laser processing

The process of copper foil removal prior to laser processing - which is necessary in the case of RCC - is no longer needed.

merit

Part2

Compared with photo-via materialsSuperior freedom in design

When stacking multiple insulating layers, via processing can be accomplished not only between layers 1-2 but also between layers 1-3.

When stacking multiple insulating layers, via processing can be accomplished not only between layers 1-2 but also between layers 1-3.

merit

Part3

Variety/grade

| Variety | Features |

|---|---|

| GX-92 | Standard |

| GX-T31 | Low surface roughness, Low CTE |

| GZ-41 | Low surface roughness, Low CTE, High Tg |

| GL-102 | Low surface roughness, Low dielectric loss tangent, Low CTE, High Tg |

タイトル

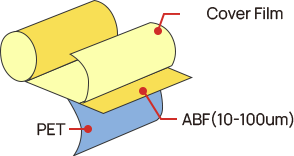

Composition

Three-layer structure: Support medium (PET), ABF resin, and protective film

Instructions for use

After lamination on the substrate, the wiring is formed through various processes.